If you're thinking about starting a laser engraving business, you're a smart one. As a laser engraver, you can carve out a niche for yourself in your local community and finally fulfill your dream of being your own boss. There are many opportunities to make money, and as the population grows, they will only continue to grow. Read on to learn how to make money with a laser engraver and find out the answer to the question, "Is a laser engraving business profitable?

Is a Laser Engraving Business Profitable?

A laser engraving business can be very lucrative as long as you are willing to work hard and pass due process. Like any business, the laser engraving industry doesn't give money. You need to do market research, find out what is needed in your area, and work on creating a brand that connects with your target market.

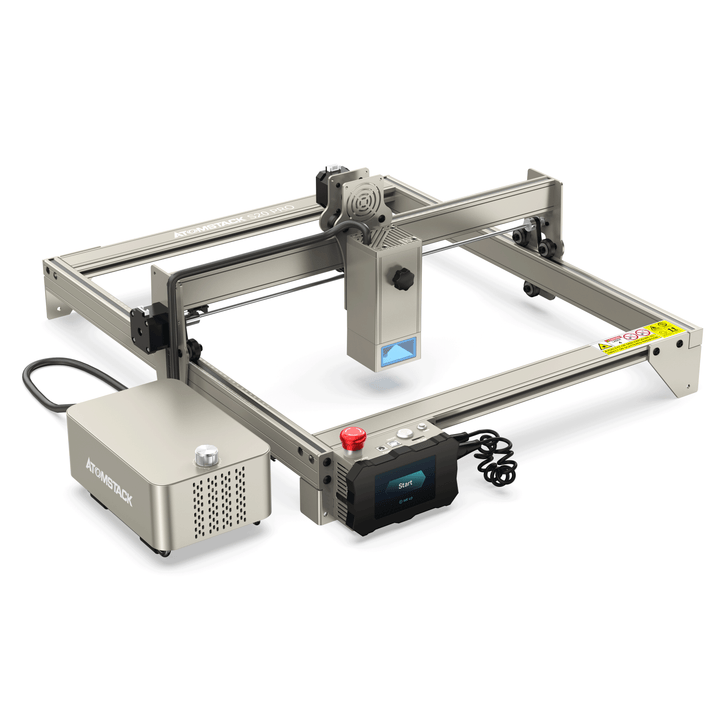

Fortunately, laser engraved products are great for manufacturing and selling for a number of reasons, starting with the low overhead associated with laser processing. Atomstack s20 pro Laser engravers are the biggest investment, and with recent market changes, you can get high-powered lasers for a fraction of the cost of the past. You need to spend a little money on equipment, build a website and promote your name there, but it doesn't have to be expensive.

Many people think of trophies and gifts when they think of laser marking or engraving, and while they can make money, if profit margins are a priority, you'd better think bigger. Getting bulk orders from corporate or industrial laser engraving customers is where the big money is made, and we'll talk more about that later.

The Benefits of Starting a Laser Engraving Business

Let’s take a look at some of the main reasons to start a laser engraving business:

Profit: The beauty of a atomstack a5 pro laser engraver is that you can turn a bland or ordinary object into something custom. Personalization is one of the biggest consumer trends right now, and laser engravers can take advantage of this directly. What's more, you use a simple material like acrylic, but turn it into something special that people are willing to pay dearly for.

Speed: One of the reasons laser engravers are so profitable is that you can quickly create custom products. Laser technology allows you to add designs to surfaces in seconds, much faster than any traditional hand engraver.

Accuracy: Laser technology is special because it is so accurate. The smaller the laser beam, the more detailed and clear your designs will be, and the more you can charge per unit.

Environmentally friendly: There are no chemical elements in your laser engraving machine and no limited resources such as ink are used. As long as you take good care of your machine, it can last for years without much maintenance.

Overhead: A laser engraver is a one-time cost with a small investment, and once it's up and running, you can quickly pay for it. They usually don't require much in the way of replacing parts and can last for years. As a laser engraver, you can break even quickly, which is one of the reasons it has such an attractive prospect.

Convenience: Not only should your laser machine come with a detailed manual, but the best manufacturers make sure they have top-notch support and a curated online support community so you can get answers to any questions you have.

What can I sculpt professionally?

After stepping through the laser engraving business, we'll detail which industries are most likely to make money. Here is a list of some of the most popular laser engraving business ideas:

company logo

signage

christmas ornaments

spice jar

QR and Barcodes for Industrial Customers

photo engraving

Personalized Products

business card

wine glass

key chain

custom jewelry

themed toy box

coaster

artwork

medical equipment

Gifts for Celebrations and Special Occasions

custom metal cup

Starting a Laser Engraving Business: Seven Steps

Step 1: Create a plan for your business

While it's understandable that you're excited and want to get started as a atomstack s10 pro laser engraver as soon as possible, never skip making a business plan. Remember, a large percentage of businesses don't have long-term success, but that's usually because they haven't planned carefully enough.

Start by delving into laser engraving technology and the industry as a whole. Determine the structure of your laser engraving business and mention the laser products you plan to create and who you will sell them to. Finally, you need to have a short-, medium- and long-term plan for how you will make money, from buying equipment to marketing and pricing.

Market analysis involves investigating industry needs in your region and beyond. Remember, thanks to the internet, you are no longer limited to selling locally. Therefore, you need to choose a segment and understand the market forces driving that segment. Consider the following questions:

How are you going to differentiate your laser engraving business?

How do you intend to add value to your customers' lives?

How will you deliver a great customer experience?

Now that you know who you're selling to, it's time to create a brand that bridges the gap between what your potential customers want and what your company offers. Key components of brand identity include:

Fonts, colors and images relevant to your company

Step Three: Pricing Your Laser Engraving Business

Marketing is only half the battle. As with any industry, laser engraving pricing is a key driver of your business. For example, when it comes to making gifts and trophies, many consumers only focus on price when choosing a custom laser engraver. If you're planning to get into this space, you'll need to find a way to ensure your prices are lower than your competitors, while still providing a high-quality service.

On the other hand, corporate and industrial customers may see low prices as a sign of poor quality. They may focus on quality, track record and accuracy. When starting out, you can demonstrate the level of quality you provide in your website, communications, and examples.

Step 4: Get the laser engraving machine equipment

Now that you've made a plan, it's time to take action. You can find atomstack laser engravers for a fraction of the price in the past. Pay close attention to the size of the engraving bed, as this determines what you can make. Some laser cutters come with adjustable beds for extra flexibility. Laser power and wattage also affect the speed and efficiency of your work

You need to find out what materials your laser can use, and raw materials are your other major cost. Other items you'll need to get started are a computer, photo editing software, a content management system, web hosting, and office materials.

Step 5: Register Your Laser Engraver Business

If you plan to become a high-flying laser engraving expert, you should register your company as soon as possible. If something goes wrong and a client sues you, you may be personally liable if you are not registered as a business. Registration can also satisfy other legal requirements, such as setting up taxes, opening a business bank account and applying for credit.

Step 6: Build a Laser Business Website

Now is the time to create a website with your branding and marketing strategy. Many people are content with setting up social media pages, or write themselves down because they're not tech-savvy enough to take that step. This is a huge mistake in today's market where you can build a website for your laser engraving business with very little coding or website building knowledge. There are many CMSs to choose from, making your website setup as easy as using MS Word.

Step 7: Start Making Custom Engravings

you succeeded. Becoming a laser engraving entrepreneur is not difficult, but it takes effort. However, in return for this effort, you can work your way, create a project of your choice and earn tons of cash!

What are the most profitable areas of laser engraving?

Now that we've established that we can make a laser engraving business profitable, let's delve into the most profitable ways to use laser engraving technology. When it comes to making big bucks in any industry, there are two main ways of doing business: quality or quantity. You can charge higher prices if you only market yourself with fine materials and high-end brands.

Alternatively, you can work with industrial and corporate clients that require bulk engraving services. From making beautiful monthly employee plaques to etching codes into manufacturing tools, laser engraving can make a lot of money in these areas. According to the U.S. Bureau of Labor Statistics, aerospace, professional design, casting, and metalworking are the highest-paid industries for etching and engravers.